After Akoya Pearl Harvest - How Is The Conceptual Knowledge of Pearl Processing Process

Last time ,we introduced our akoya pearl farm base ,and learned the process of nucleation in pearl farming. Now we need come to another topic, after pearls are harvested ,what we need to do .

Cultured pearls are harvested from the pearl farms after a nucleation period of 8 months to 6 years. Akoya pearls are typically cultured from 8 months to 2 years, while freshwater, South Sea and Tahitian pearls are cultured from 2-6 years.

Pearls are almost universally harvested in the winter. Cold water slowed the metabolism of the host oyster, slowing the pearl formation process that causes the nacre to be formed in tighter layers giving the pearl their maximum luster.

The actual harvest begins when the pearls are brought to bay from their mooring positions. The pearls are then opened individually and the pearl or pearls extracted. In the case of akoya oysters and freshwater mussels, the shell and meat are moved or used for another purpose,for example, shell is used to create mother pearl products and the muscle tissue is a little known delicacy it is eaten raw is quite delicious or sold in market by employee.

Next ,the pearls are seperated from the soft tissues, these machines spin the pearls out of tissues of the oyster.Fresh seawater is being added to dilute the solution a small amount of detergent is added as well.It takes about one minute of spinning for the pearls to be separated from the tissues because the pearls are heavier they go to the bottom of the barrel. After this the pearl are now being rinsed and separated from the little bit of remaining soft tissue another debris.After all the pearls are harvested they are then cleaned of debris and polished, to bring out a higher luster.

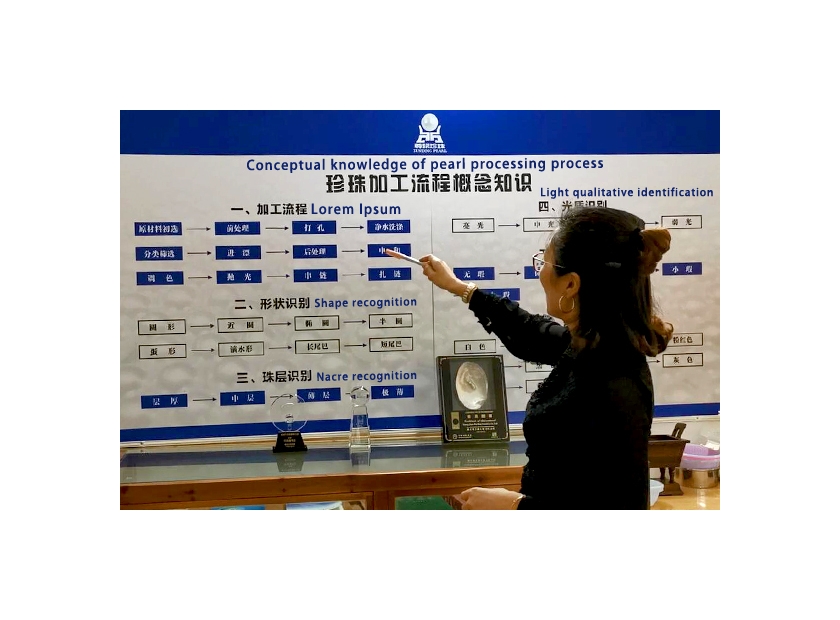

After the pearls have been cleaned and polished, they are sorted by quality and size categories,lower quality pearls are often ground up for medicinal uses and creams.Many of these pearls may then go through further treatment,sorting,matching,drilling,grading and polishing.In factory, the pearls are first sorted by size using sieves,that why akoya pearls are always measured in half millimeter sizes.Next the coil pearls are served by body color overtone color and luster and choose the best one,and then the pearls are being separated into half drill versus full drill qualities and half drilled pearls are used for areas as pendants and rings.It should only have one blemish or be limited to blemishes in only one area of the pearl so that the base of the pearl is clean,full drill pearls are used for necklaces bracelets and other types of jewelry,requiring a hole to be drilled completely through the pearl . Further sorted by quality ,which based on their luster and blemishes.

Marking pearls for drilling is a very time-consuming process and only the most quality conscious factores take the time to do the before drilling pearls. Each pearls carefully are examined to determine the best location for the drill hole if there is only a single belmish on the pearl ,the pearl is generally drilled directly through that blemish so the pearl is essentially blemish free after drilling,it is normal for pearl have blemish.A skilled technician can drill approximately 500 pearls an hour,it takes years of practice to become this proficient,if the bits hit the pearl too quickly for this,we’ll jump a little scratching prolong on the drill hole. Likewise if they are drilled too quickly excessive ,heat will build up and crack the pearl.

The drilling process created a lot of pearl dust and the pearls need to be washed to remove any pearl dust left on the pearls and in the drill holes pearl dust is very abrasive and if it is not removed ,it will eventually wear through the silk cord. The pearls are placed in a centrifuge which sends any excess water off the pearl and out of the drill holes.

Akoya pearls need to be polished in a simple non intrusive process to truly bring out their natural beauty,. A good harvest is determined by the number of marketable pearls produced in relation to the number of oysters that were nucleated. The percentage of pearls that are considered high-quality will determine the success of the enterprise. On average, only half of the pearls will be marketable, and less than 10% of these will be considered top-quality.

A good harvest is determined by the number of marketable pearls produced in relation to the number of oysters that were nucleated. The percentage of pearls that are considered high-quality will determine the success of the enterprise. On average, only half of the pearls will be marketable, and less than 10% of these will be considered top-quality.